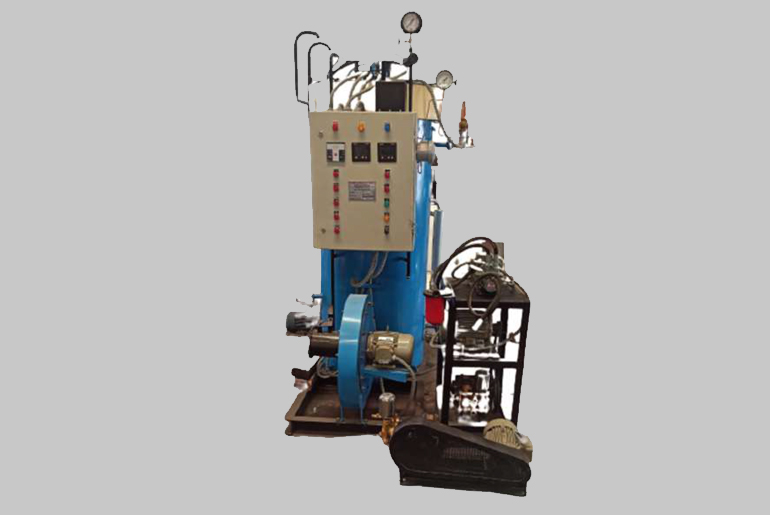

Industrial IBR Steam Boilers Manufacturers in India

we are in eminent name which is engaged in Manufacturing Industrial Steam Boiler, Industrial Boiler, Industrial Ibr Boiler, Industrial Boilers In Hyderabad Telangana India. Industrial Steam Boilers are an essential part of many industrial processes, providing a reliable and efficient source of heat and power. These Boilers are used in a wide range of industries, from manufacturing and food processing to oil and gas production and power generation. In this article, we will take a closer look at what industrial steam boilers are, how they work, and why they are so important.

What is an Industrial Steam Boiler?

An Industrial Steam Boiler is a large vessel that is used to produce steam for various industrial processes. Steam is a vital component in many industries, as it is used for heating, sterilization, power generation, and other applications. These Industrial Steam Boiler are typically large, complex machines that are designed to withstand high pressure and temperature to produce large quantities of steam.

How do Industrial Steam Boiler work?

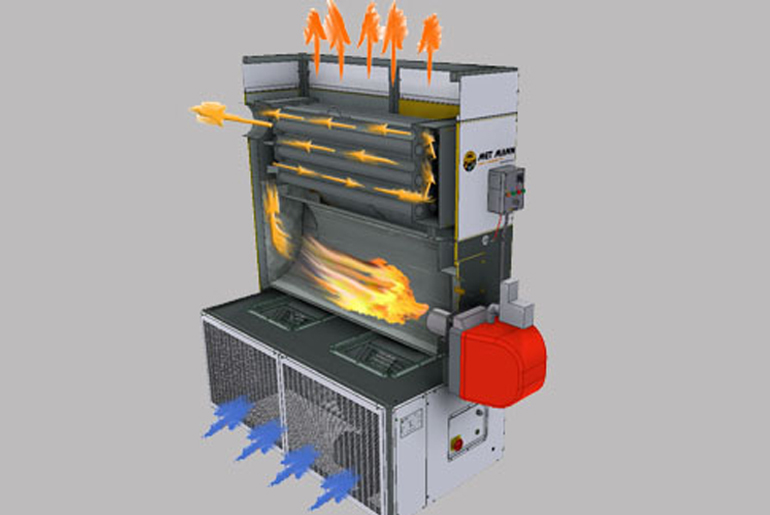

Industrial Steam Boiler work by heating water to its boiling point and then converting it into steam. The process starts with the boiler's burner, which ignites fuel such as natural gas, oil, or coal, to heat up the boiler's tubes. The heated tubes transfer the heat to the water, which turns into steam and is then distributed throughout the building or used for industrial processes.

The two most common types ofindustrial steam boilers are fire tube and water tube boilers. In a fire tube boiler, the hot gases produced by the burner pass through the tubes and heat the water surrounding them. In a water tube boiler, the water is heated in the tubes, and the hot gases pass around them. Fire tube boilers are commonly used for low-pressure steam production, while water tube boilers are preferred for high-pressure applications.

Why are Industrial Steam Boiler important?

Industrial steam boilers are an essential part of many industrial processes, providing a reliable and efficient source of heat and power. Here are some of the key reasons why these boilers are so important:

1. Versatility: Industrial Steam Boiler can be used for a wide range of applications, from heating and sterilization to power generation and food processing. This versatility makes them an invaluable asset for many industries, as they can adapt to different production needs.

2. Efficiency: Steam is an efficient and cost-effective way to transfer heat, making industrial steam boilers an economical choice for many businesses. With the advancements in technology, modern boilers are designed to maximize efficiency and reduce energy consumption, resulting in significant cost savings for companies.

3. Reliability: Industrial processes often require a constant and reliable source of heat and power. Steam boilers are designed to operate continuously, providing a steady supply of steam without interruptions, making them a dependable source of heat and power for industrial processes.

4. Safety: With the use of advanced technology and safety features, industrial steam boilers are built to withstand high temperatures and pressures. This makes them a safe and reliable option for industrial processes, ensuring the safety of workers and the environment.

5. Environmental benefits: Industrial steam boilers can be powered by a variety of fuels, including natural gas, oil, and biomass. This flexibility allows businesses to choose the most environmentally friendly option, reducing their carbon footprint and contributing to a cleaner and greener environment.

In conclusion, Industrial Steam Boiler are an integral part of many industrial processes, providing a reliable and efficient source of heat and power. They offer versatility, efficiency, reliability, safety, and environmental benefits, making them a crucial component of various industries. As technology continues to advance, we can expect to see even more efficient and sustainable steam boilers in the future, helping businesses to reduce costs and improve their environmental impact.